Rockriver.us

Rockriver.us

<

PREVIOUS PAGE

NEXT PAGE >>

More turbine install

Here is a picture of where the 8-3 with ground UF underground cable

enters the power station. You see two more black lightning arrestors

mounted to the side of the 4" square metal box. Here I am preotecting

the 3

hotwires from the turbine again. I have 2 arrestors at the base of the

tower and two more here. This is to provide extra protection to the

ARE wind turbine controller and Outback FM80 wind controller which

contains sensitive

electronics. This equipment really needs to be protected. You see on

the bottom of the 4 inch box, there is a large wire coming out from the

bottom. This wire is a ground wire that I ran directly from the ground

rod outside the shack over to this box. This ground wire is

specifically for the ground wires of the lighning arrestors to connect

to. Normally you would just wire the lightning arrestors ground wires

to the normal ground that runs from the box over to the ground in the

controller and then to the outback FM80 and then to the FW-DC

ditribution panel's ground. To me this

does not make good sense. Why would you want to direct thigh voltage

lightning over to the grounds located in your controllers and

distribution equipment? Instead I think it is better to isolate the

lightning and direct it straight to the ground rod and bypass the

grounds in the equipment.

I used 1" pvc conduit from the top of this box, across the ceiling and

down to the ARE turbine controller box. The 4 inch box came with

only 1/2 inch

knockouts which accomodated the arrestors ok but I had to drill a 1

inch hole for the 1" pvc connector. I used a 1" in hole saw and a

cordless drill.

Below (left picture) is a picture of the ARE wind turbine

controller on the left and

the

diversion load on the right. Picture on the right does not show the

Outback FM80 wich would be mounted to the left of the ARE controller

because the FM80 did not come till much late in the

installation. Neither of these boxes is that heavy. I

just used some deck screws and washers to mount these to the 3/4 inch

plywood. The diversion load is made up of 6 light

sockets with these screw in heating elements. The screw in just like a

regular light bulb. I had to use another piece of plywood to mount the

diversion load

to. I also needed to pay special attention to how close the diversion

load was in relation to its surroundings. A.R.E recommends keeping it

away from anything 18 inches above, and 12 inches on all other sides.

Of course you would not have anything anywhere near the front of it

because these things can glow red hot and possibly cause a

fire!!

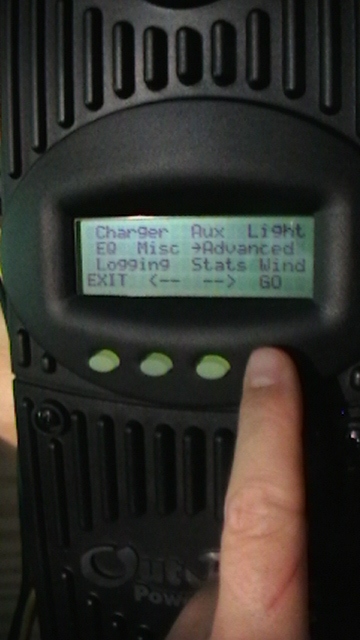

Below is a closer view of the worlds first (i believe) MPPT wind

turbine contoller (for battery charging)

made by

Outback for the ARE 110 - 2.5 kw wind turbine. Outback

has modified the FM80 and programmed it with a new mathematical

algorithm so that it will work with ARE's wind turbine. Its

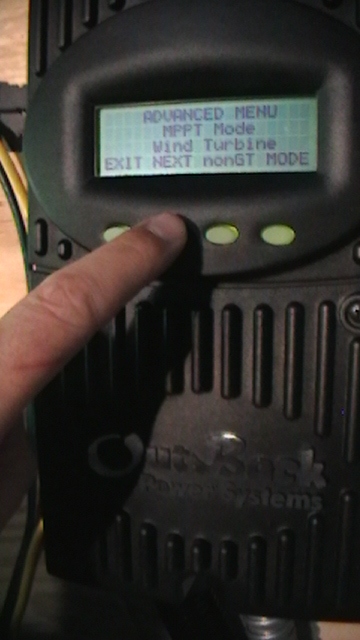

called the Windtracker 80. If you go under the

advanced menu

then under MPPT mode, you can change the mode to wind turbine.

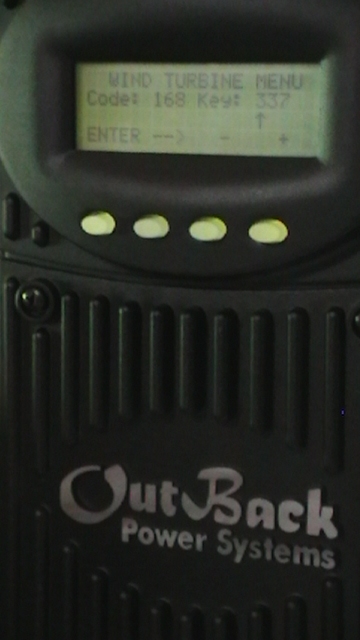

There is also a "Wind" menu which displays a code and a key. I found

out from ARE that this is the password protection in order to get into

the FM-80 and change the power curve information. This means that

theoretically , if you new the code then you could adjust the power

curve settings to work with a home Brew Axial flux wind turbine or any

other turbine for that matter. Outback and ARE are the only ones with

the passcode and will not give it out.

See below:

The picture below

on the left shows the modified FM80.

The picture below

on the right shows the Outback modified FM80 wind

controller mounted to the left of the ARE controller. I waited for this

controller for about a year an finally received it on September 18 2008.

ARE and Outback took a long time to work things out with testing,

equipment lableing, manuals, and testing of prototypes.They finally

pulled through. Before I got the outback,

my turbine (in 25 to 30 MPH winds) would only put out about

800 watts , wide open just before furling.

Now.. with the Outback, in estimated wind speeds of 15 to 20 MPH winds

, the Outback FM80 was showing readings

between 1000 to 1500 watts output ( I do not have an annenometer so I

am approximating the wind speed with the Beaufort scale techniques so

these are just ESTIMATIONS on wind speeds). This morning (sept 20 2008)

there

were

some pretty good gusts of wind and the turbine was putting out

sustained 2500 to 3000 watts ( at this time the wind turbine never

furled) . The ARE turbine is only rated for 2500

watts. Pretty impressive. I can't wait to see the output in some 25 to

30 mph winds. It is interesting that Outback Power has not made any

kind of announcement or anything about this new controller as of sept

2008. This is the

first MPPT wind controller anywhere in the world that I know of

thats made specifically for battery charging!!!!! and will

revolutionize the wind industry as we know it. I believe it will only

be a matter of time before other turbine manufacturers like Proven and

Bergy start working with Outback Power to make MPPT controllers for

their battery charging turbines as well.

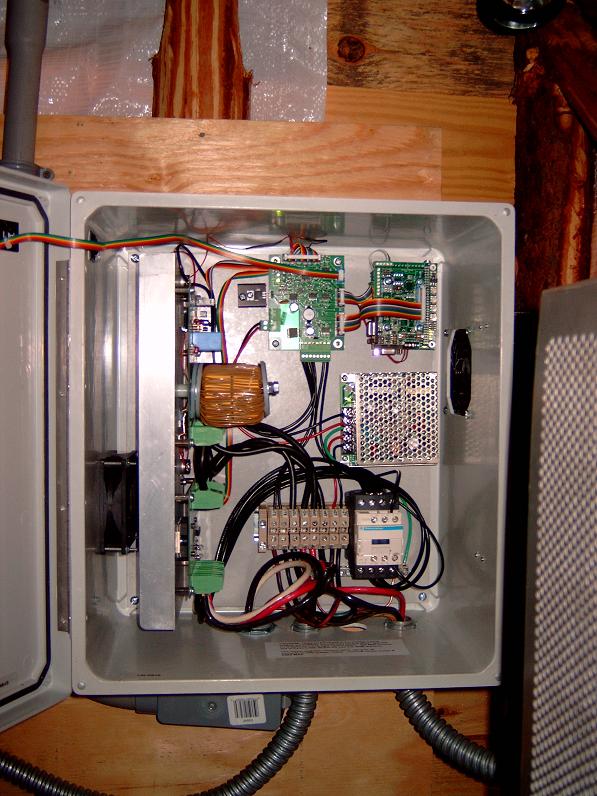

Below is a shot of the inside of the ARE controller.

I used

1" rigid pvc for the conduit and #8 THHN wire between the 4 "

square box

(the one that I refered to earlier where the turbine wires enter the

building and had 2 lightning arrestors) and the bottom of the ARE

controller box transtioning into the the LB/ aka a sharp elbow with a

cover on it. There was a reason for the LB. ARE only puts conduit

knockouts in the bottom of their controller box. From the 4" metal box

I went out of the top, across the ceiling and down the left side of the

controller box and back up into the bottom of the controller box with

the LB. I personally think that having a knockout or two on the top of

the controller box would be an inprovement. ARE says you void the

warrantee if you drill new holes so I opted for the funky conduit run.

I

used 3/4 metal flexible conduit and # 8 THHN copper wires to run from

the ARE controller to

the diversion load. I used 3/4 metal flexible conduit and 6-3

thhn wire (I ran out of 8-3) from the ARE controller to the Outback

FM80 MPPT

wind turbine controller (A specially modified FM80- tentatively called

the

Windtracker 80). I used a plactic flex conduit that I found and have no

idea where it came from along with 6-3 to go from the FM-80 MPPT wind

controller to the FW-DC

distribution panel. I also needed to run #10 solid from the ARE

controller

mother board to the DC bussbar in the FW-DC to power up the

controller mother board and electronics. I ran the #10 in the same

conduit as the 6-3 thhn wire.

Initially , the ARE controller connected directly to the FW-DC. But,

after the FM80 finally came (after a year of waiting) I had to add the

FM80 in between the ARE controller and the FW-DC.

CLICK the manual link to download the A.R.E. 48V wind turbine manual.

NEXT PAGE >>

Rockriver.us

Rockriver.us Rockriver.us

Rockriver.us