Rockriver.us

Rockriver.us

< PREVIOUS PAGE

NEXT PAGE >>

This next section will discuss what equipment I decided to buy, what it

cost me, and why I chose it.

As you could imagine, I did alot of calling around

to different

equipment vendors trying to decide what equipment to buy. Also in order

to get the North Carolina state tax write off and federal tax write

off, my installation has to meet State North Carolina code and pass

State inspection. I went down to Pittsboro and pulled a mechanical

permit (for

the tower) and an electrical permit (for solar and electrical install).

As far as the tower is involved, the inspection department had no

idea how to inspect it because their mechanical code books do not cover

towers so I will have to provide engineer stamped tower drawings from

A.R.E which they have already provided me. The project type was labled

gas backup generator which I thought was wrong but after asking the

inspection department about the miscategorization of my permit, they

said that it was the only category they had for that type of work.

The five biggest costs were:

- Inverters

- solar panels

- wind turbine

- wire

- batteries

Inverters:

I realized that many of the appliances in my home

needed 240 volts to run. For example, my electric dryer, my hot water

heater, range stove, well pump, 2 heat pumps all use 240 volts. Now

don't get me wrong,

it would be way too expensive for me to have an installation that would

actually run all these energy hungry appliances at the same time.

However, my idea is

that if we ever did loose the electric company's grid power, we would

at least

have the option to run any equipment that needed 240 volts individually

at our discretion. Not to

mention that if we did have a power outage I wanted to be able to run

my system as a backup to power any appliance in my house (assuming my

batteries had enough juice or if the wind was blowing hard enough for

the windmill to provide enough output) when the electric company's

grid was down, similar to how folks will use

gas generators to power their house during outages.

At the time, there

were no manufactureres who had an inverter that would do 240v on its

own, the usual case was to use two seperate inverters

(although in the last few months Xantrex came out with one that would

do 240v, the XW

series). The way they usually get 240v was to have 2 inverters that are

installed side by side and then a communication cable connects the two

and synchronizes the frequencies together to get synchronized 240v. I

went with Outback Power inverters. The reason I chose outback was for

two reasons. Firstly, the consultant I spoke with talked highly

of

them . Secondly, about 90 percent of the equipment dealers I called

recommended Outback over Xantrex and actually used Outback personally.

Other folks experience was good enough for me so I listened and went

with Outback. Also, Outback inverters are made in the U.S.A. I

purchased

my two inverters and flexware components from http://www.affordable-solar.com

. They have some pretty good prices. The inverters were $1688.00 each.

Solar panels:

As far as solar panels, I ended up going with

Evergreen Solar. The majority of folks I

talked too said they really liked the sturdiness of the aluminum

frames. After buying them I have to agree that the frames are sturdy

and can easily be screwed into with self tapping screws ( for custom

mounting as in my case) but the biggest selling point was the cost. I

was able to get (4) 190 watt Evergreen solar panels (ES-190-RL) from

http://www.affordable-solar.com

for $899

each. I only bought (4) panels

because that was all I could afford. Also, Evergreen panels are made

right here in the U.S.A. Evergreen panels were actually the cheapest I

could find

comparing all other brands and spending hours on the internet searching

for the best deal on panels.

**Panels

UPDATE** On October 1st 2008 I

purchased 12 more panels. Unfortunately I could not find any Evergreen

solar panels anywhere in the united States. I called probably 20

different dealers and no one can get them. Apparently Evergreen is

shipping all their panels to Europe because demand is so high. What I

ended up buying is (12) KD205GX-LP Kyocera 205 watt panels. The VMP or

VMPP (voltage-maximum power) on the Kyroceras is very close to my

Evergreen ES-190's. Its best to match the the VMP when mixing different

panels.

I bought the panels at www.wholesalesolar.com for $910 each with

shipping around $600 bucks. These panels were not put into service

until January of 2009.

Wind turbine:

With regard to the wind turbine

the first thing I would tell you is order it as soon as you can. This

will save you alot of headaches as far as getting on very long waiting

lists. Waiting on my wind turbine and tower parts have been the biggest

annoyance for me. I did alot of research and spoke with many folks on

turbines, quality, efficency, etc. I finally narrowed the list down to

"Proven" wind turbines out of Scottland or A.R.E (Abundant Renewable

Energy) out of Oregon. The Proven wind turbine seemed to

be a good choice. However shipping from Scottland was starting to look

like a bit of a headache and would cost alot as well. I eventually

ended up going with A.R.E. Their turbines are made in the U.S.A and I

felt that getting spare parts or possible returns would be easier than

getting service from overseas.

Since I wanted to have battery backup, I

opted for the A.R.E. 110 low voltage turbine (48 volt version, rated at

2.5 kw )

which could charge up my L16H trojan batteries (http://www.abundantre.com).

ARE's ( battery charging model) wind turbines

are the first in the industry (I believe) to

have a MPPT controller specifically for battery charging. Until now,

Mutil Power Point Tracking was

always associated with Solar panels or high voltage wind turbine grid

tie. Well not anymore!!! The

turbine still produces 3 phase wild AC like the high voltage

(non-battery charging- grid tie model), however the A/C voltages

are a bit lower. I

also needed a tower for the turbine. After reading a bit about

different towers, the majority of folks indicated that the biggest

mistake that turbine installers make is the tower is too short. Knowing

this I decided to buy the 106 foot (tilt up) tower straight from A.R.E.

- A.R.E 2.5 kw turbine cost (including ARE controller,

the Outback MPPT charge

controller, and

the diversion load ) was $8,870

- A.R.E. 106 foot tilt

up tower (include hardware, guy wires, everything for finished tower)

was $4400

- shipping was $1850

- ARE is currently the only wind turbine manufacturer in the world (I

believe) with a working Multi Power

Point Tracking controller for battery charging (low voltage) wind

turbines.

Their controller is specially made by Outback Power systems and is

called the windtracker 80 (a modified Flexmax 80) - Here is a link to

the manual- refer to page 6 and page 8 for references to the new

outback wind MPPT controller: http://www.abundantre.com/ARE110-48V_Owners_Manual_Electrical_Ver4.3.pdf

Wire:

The other large cost was wire. As you

can see I ended up needing about 1500 feet of #2 for the AC runs from

my house to the power station (a tin roof shack I built out of the

trees that we cleared to allow for the turbine) and using left over #2

for the 50 foot DC feeds from the solar panels to the power

station. Iwas able to get the wire for $1.18 per foot from Lowes

in June 2007 so about $1800 dollars. I checked prices the other day

12-20-07 and prices had jumped to $1.98, so copper prices have

gone up .80 cents already. I guess I was lucky getting it when I did. I

also needed 70 or so foot plus another 106 feet (to go up the turbine

tower) of 8-3 with ground UF (underground) cable for the turbine. The

UF cable was $2.45 a foot so about $450 bucks. I used UF because it was

quick and easy and very durable for going up the tower to the turbine

Yaw assembly. Also NEC code does not require it to be in conduit under

ground. Just dig a ditch and drop it in. I also bought around 12 feet

of 3/0 awg for connecting my (8) 6 volt trojan L-16-H batteries

in series to get 48volts and also for the positive and negative feed

from the batteries up to the main pos and neg busbar in the back of the

DC distribution panel. I'll get into DCand AC distribution later.

As

far as conduit

for the # 2 thhn wire between my house and the power station (tin roof

shack) is concerned, I referred to the NEC 2005 code Annex-C pg 70-704

to get 2" rigid PVC for #2 THHN type wire. 2" pvc supports up to 11

conductors. I only have six in this case (2 neutrals and four hots) but

wanted plenty of room in the pipe for pulling the wire. From the power

station to the panels I user 1" rigid pvc to support (2) #2 thhn wires

for positive and negative. Annex-C

pg 70-704 says max of (3) #2 wires in a 1" rigid pvc. When buying

conduit buy plenty of extra couplings, connectors, locknuts and glue.

I can't tell you how many trips I made to Lowes for that one connector,

coupling, or elbow that I forgot about. Keep your receipts and when you

are done just take the extra stuff back and get your money back.

Regarding the wire sizes. This was a little tricky in my situation.

Initially I was going to have the power station closer to the house

which would in turn reduce wire size, conduit size, etc. Then I thought

about the possibility of fire or battery hydrogen gases within the

power station. I figured that it is best to keep this away from the

house. Also, you have greater voltage drop with DC voltage than

you do with A/C voltage so having the A/C feeds go from my house all

the way out to the power shed is not a problem. If I had the D/C feeds

from the turbine and panels come all the way back to my house (assuming

now that the inverters and batteries are in my house now) then voltage

drop for the DC would be a big problem because wire size would be

enormous and the cost of the wire and conduit would go up greatly. My

idea was to have the power station

further from my house for saftey reasons and closer to the solar panels

to reduce DC voltage drop. In this case given the distance from my

house to the shack (200 feet)

I needed to figure out how many amps I really needed at a given time. When

you double your voltage you halve your amperage. So what wire size do I

need to go from my house to the power station ?

My

service entrance is 200 amps but I never use 200 amps. I estimated that

the maximum amps I would ever use at a given time would be 100 amps.

This would be the case of microwave, water pump, evaporator coil blower

unit, lights, shop tools, etc all going at the same time. So I need

100 amps right? Ok so I am going to have 2 outback inverters to give me

240 volts. Assuming I have my loads balanced across my backup panel's 2

hot busses this means I need to be able to draw from the inverter 50

amps per leg. But wait, the way the inverters work is this. When you

are grid tied (which in my case I am but with a battery backup) the

inverters synchronize with the grid. When you are using more power than

you produce from your solar or wind you draw power from the grid. In my

case if I were using more power than I produced I would draw power from

the grid but the actual distance the wire runs is this: Wires run from

the meter base to the grid tie panel->through 2" conduit across the

house--> out of the house through the ground to the shack-. into the

shack then into the inverters--> through the inverters internal

transfer switch--> out of the inverters back into 2" pvc

conduit-->into the ground back to my house across the house and into

my "backup panel" where all my branch circuit are. So, what I needed to

figure out was the voltage drop for 200 feet x 2. So voltage drop for a

400 foot run at 240 volts needing 50 amps turned out to be #2 with

3.33 % voltage drop. One thing I will note here is that the outback

inverters actually let you raise or lower the output voltage so

theoretically you could minimize voltage drop by raising the output

voltage. However, I am calculating voltage drop anyway and buying the

wire size accordingly as you normally would as extra assurance that the

wire size is sufficient for the load. Each outback inverters

internal transfer switch

can

handle a maximum of 60 amps, so 60 amps per inverter = 120 amps total

so long as my loads are balanced. The way I found my wire size was with

a handy dandy

voltage drop calculator. There are several on the internet and the one

I used can be found at http://www.mikeholt.com/technical.php?id=technicalvoltagedrop

In the case of both of my heat

pumps, the

electric dryer, water heater, electric range stove, these appliance's

circuits have been moved to the grid tie panel. This

essentially means

that in the case of a power failure I can't run these heavy load

circuits but I can still cook with the microwave and

get water with the well pump, light my house, use any receptacle in the

house, and run the single

evaporator coil blower unit to circulate heat from my woodstove

throughout my house.

The

reason for this is that if I left them on the backup panel (original

main panel) then they would draw alot of current through the inverters

possibly overloading them (each inverter is only good for 60 amps each

for passthrough voltage (passthrough voltage meaning the inverters

passing grid voltage through them over to the back up circuit/backup

panel). Also , If I lost grid power, I would have to run down to the

basement and turn off all the breakers for all the heavy load devices

out of fear that if something were left on then I would just suck

my batteries dry in a matter of hours, especially with the heat

pumps.

**Note about woodstove**

My wood stove is

basically a box inside of a

box (heat exchanger). The inside box is the firebox. The outside box is

the exterior of the whole unit and has two square 2 foot x 8 inch holes

on either side at the bottom for air to be drawn through across

the firebox. I cut another 12" hole in the return box of my

evaporator coil blower unit for the main floor of my house and

connected a 12 " piece of flex duct to it. I ran the 12" piece of

flex

duct down to where my wood stove is and transitioned to 12" stove pipe

which screws down to the top of the wood stove. I now have the ability

to turn the heat off on my thermostat (remember that heat pumps are on

grid tie panel and can't be run in power outage) but turn the fan

to "on". This

allows me to use the blower unit to draw air through my woodstove

-->> up the 12" duct --> through the evaporator coil

blower

unit--> and then out of the central duct system throughout my house.

In a power outage, so long as I have plenty of wood, I have central

heat since this blower is hooked up to my backup panel. The blower unit

is 240 volts (I have two inverters at 120 volts each -- sychronized

AC) and draws only about 2 amps between both hot legs so I can

run this all day with just the battery bank, or indefinitly if the wind

is blowing the turbine or the sun is

shining on my panels. The same goes for all my other "backup"

circuits. It's not uncommon for it to be 15 or 20 degrees outside and

80 degrees inside the house with the wood stove. Hot enough to open a

window or two in the middle of winter. Not bad for heating a 2400

sqaure foot house.

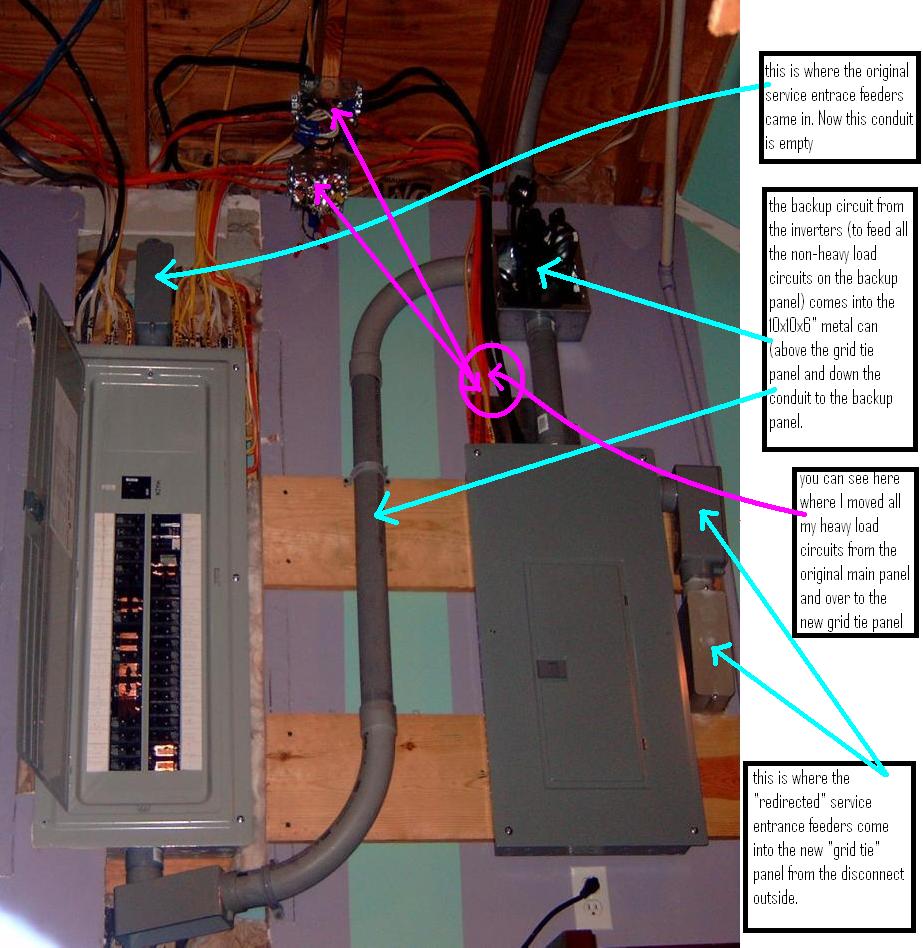

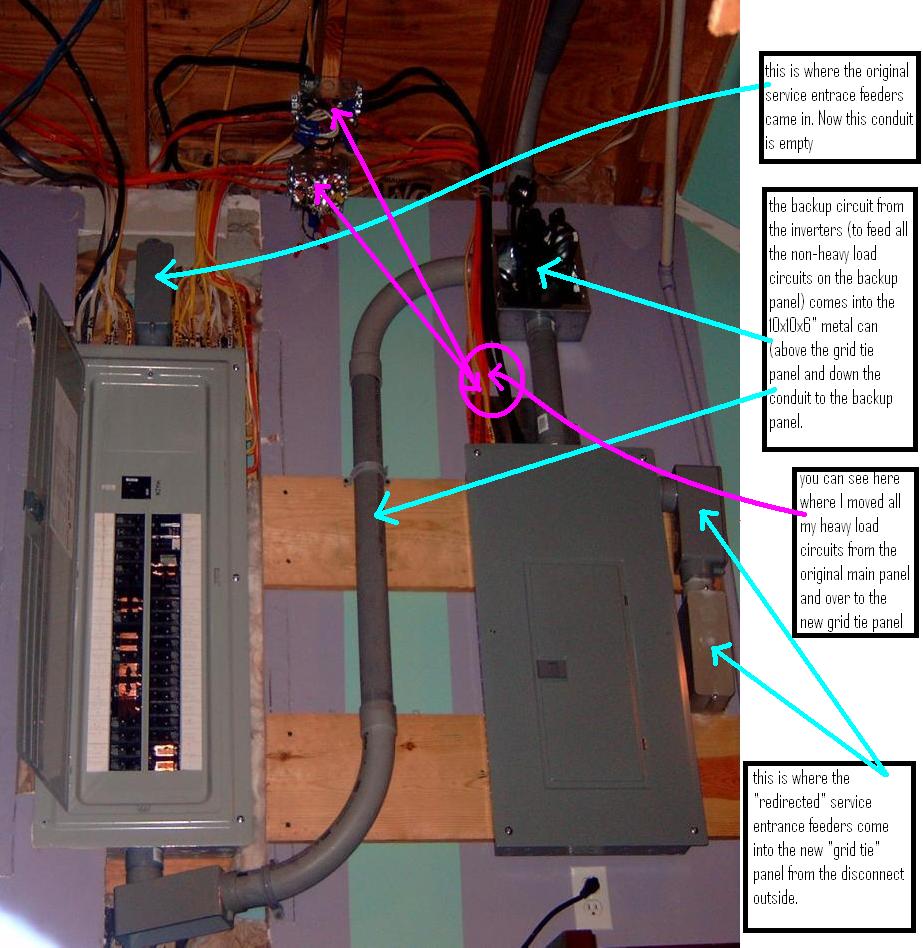

In the picture below you see two panels. My original panel is on

the left which is

now the backup

panel. The new grid

tie panel is on the right. I basically pulled the service entrance

feeders from the meter

outside and terminated them into the panel on the right (new grid tie

panel) Above the panels you see two metal

boxes which is where I made the splices for the heavy load circuits

that were moved out of the backup panel and into the new Grid tie panel.

The left panel is of course my original main panel (Siemens brand) and

the panel on the right is the "NEW" grid tie panel (SquareD brand) with

heavy load circuits and also a double pole 60 amp breaker that catches

the two 120 volt feeds (grid tie) from the two inverters out in the

power station. The grid tie panel is a 24 space 200amp panel and was

bought at lowes for $109. Fortunately the breakers from the siemens

panel on the left actually fits the Square D panel on the right so I

just pulled the breakers out on the left and plopped them into the

panel on the right and just moved the heavy load circuits onto those

breakers again. There was one exception. A double pole 50 and 60 amp

from

the Siemens panel would not fit the SquareD panel without - lets just

say some field modifications involving some lengthening of the slot on

the bottom of the breakers with a 1/4 in drill bit, so when shopping

around, take breaker/panel intercompatibility into account when looking

at different panels and breakers and planning for the future.

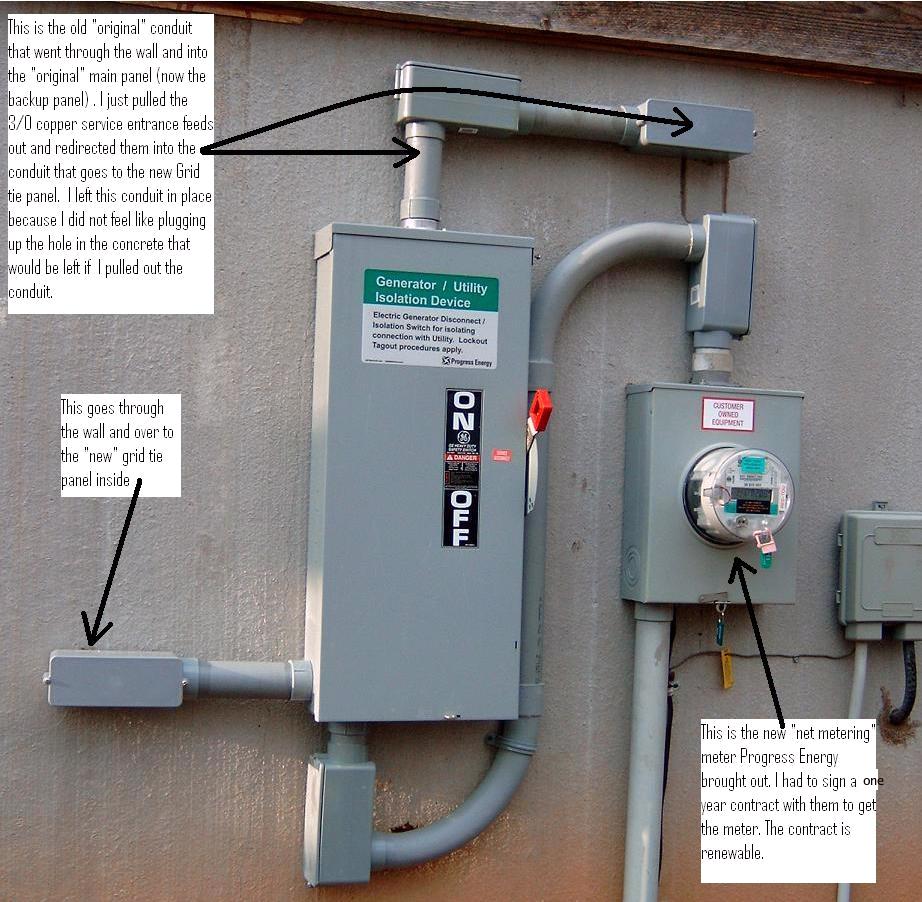

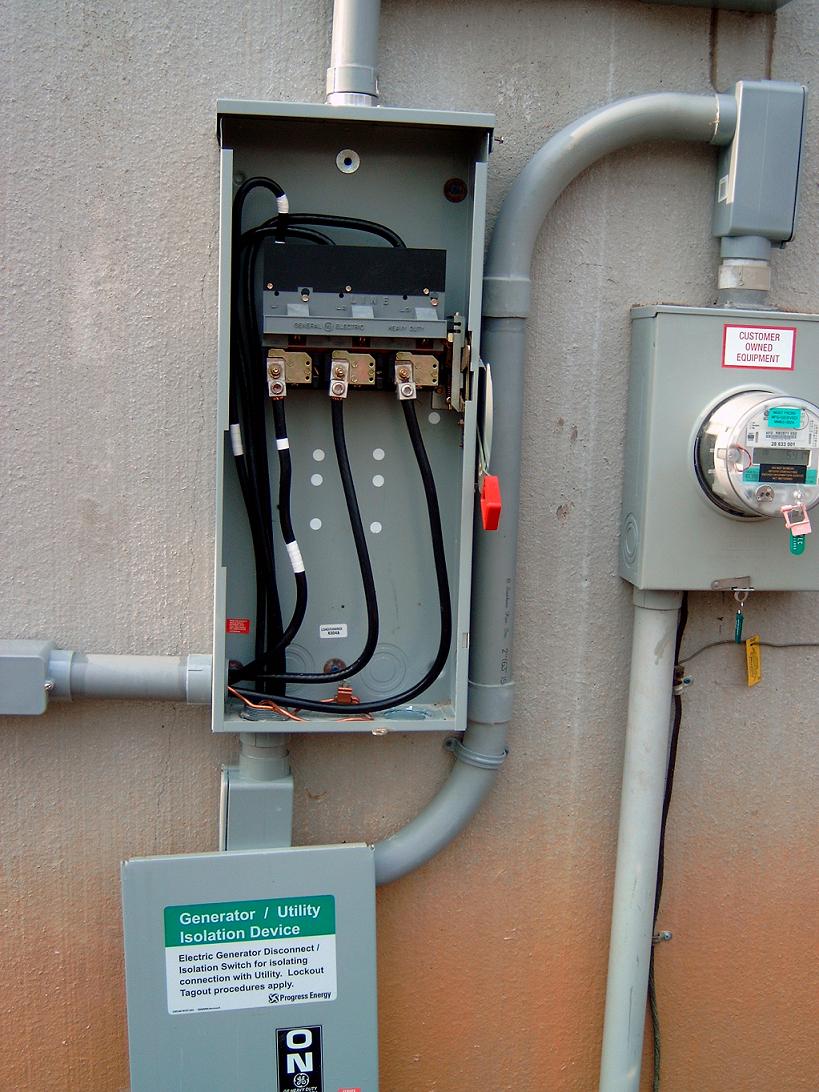

On the picture below, you will notice a sticker on the front of the GE

disconnect that says:

"Generator / Utility Isolation Device-- Electric generator Disconnect,

Isolation switch for isolating connection with Utility. Lockout Tagout

procedures apply"

This sticker was brought out by Progress Energy and stuck to the front

of my disconnect . The whole reason I have the disconnect in the first

place is because of the NEC code which requires a disconnect between

your meter and your "renewable energy source" aka the grid tie

circuit from the inverters that plugs onto a double pole 60 amp breaker

in the new grid tie panel. Remember, this whole installation has to

pass NC State electric code in order for me to legally grid tie to the

utility grid , get a net metering meter (even though they

actually

brought the meter out and installed it 6 months before I finally got it

inspected) , and of course the Federal and State government

wants me to have the install inspected before I can get that 35% tax

credit on my 2007 taxes and the 2000 bucks from the Feds.

As of February 4, 2007 I finally passed the mechanical and electrical

inspections and can now claim the State and Federal tax credit to help

pay for some

of this equipment (NC tax credit is 35% of install, fed is 30% or max

of $2000, Fed does solar but no wind, NC does credit for both

wind and solar). Here are a few links to info regarding the

North Carolina tax credit for Wind and Solar.

North Carolina Tax credit info:

http://www.dsireusa.org/library/includes/incentive2.cfm?Incentive_Code=NC20F&state=NC&CurrentPageID=1&RE=1&EE=0

http://www.dsireusa.org/library/includes/map2.cfm?state=NC¤tpageid=3

Federal tax credit info :

http://www.dsireusa.org/library/includes/incentive2.cfm?Incentive_Code=US37F&State=federal¤tpageid=1&ee=0&re=1

The mechanical part of the

inspection refers to the wind turbine tower. The inspectors have no

Idea how to inspect a tower so they requested engineer stamped drawings

from A.R.E.. They took the drawings no problem and that got me a

pass on mechanical.

The other interesting thing about this whole inspection deal is this.

When I first built my house I did not put in a disconnect between my

meter and my panel.

So when I called for inspection, I had to call Progress Energy and

schedule them to come and pull my meter out of its socket (and they

also turned

power off at the transformer - transformer is at the

road). After they pull your meter they will not put the meter back in

until you have passed inspection. Had I put in a disconnect when I

first built my house I never

would have had to call progress energy out to pull the meter because of

course I would have had a disconnect and could just kill power myself.

Having a

disconnect gives me the ability to kill power and thus do whatever I

want to and whenever I want. If I were in the middle of building

a house, I would go ahead and put in a disconnect now. It would make my

life

easier in the future.

Here is a document with the (TIME OF USE)

registers. If

you have a "time of use" TOU Meter, you can use this to figure out

what the registers mean.

I usually pay attention to registers 04, 44 (44 is not on

the document but means total KWH recieved), 45, 48, 52 and

55.

Time-of-use registers

Here is a link to Progress Energy's netmetering toolkit. At this link

you can download the application for Netmetering

(They charge $100 application fee)

in North Carolina as well as rules for interconnection

(inspection,installation policies,etc) . http://www.progress-energy.com/custservice/carres/renewables/netmetering.asp

and

http://www.progress-energy.com/environment/ras/carolinas.asp

To speak with someone directly about doing grid tie and netmetering

you can send email to customer.generation.pec@pgnmail.com

or renewablesinfo@pgnmail.com

Here is a shot of the grounding of the disconnect. What I did was had

one continuous ground (solid #4 copper) starting at the backup

panel-> following the 2"inch pvc conduit up to the 10x10x6 inch

metal can--> down into the grid tie panel and out the wall to the

outside and into this disconnect---> down the two inch conduit over

to the meter base enclosure.

The

picture below is of the disconnect . I used 3/0 for the two

hots and also the neutral. Again the ground is #4 solid. Disconnect was

bought on ebay for about $250. Its probably a $650 dollar commercial

disconnect. This type of 200 amp Nema type 3R disconnect

could NOT be bought at Lowes or HomeDepot. Nema type 3R means rated for

outside/rainproof. Anything outside needs to ne type 3R to pass code.

My

first

thought during the inspection was - oh no, this

is a renewable energy install and most inspectors have no idea about

renewable energy anyway or how to properly inspect it so my chances of

failing might be higher since the inspectors could easily be " unsure,

confused, or I need to call my Electrician contacts to verify this" .

The honest truth is that renewable energy installs are pretty few and

far between in my area and the inspectors have very little experience

and exposure. Luckily Ipassed with no problem. The only thing the

inspector did say was that I needed to mark all my neutral feeds with

white tape. I missed a few but corrected them while he was there.

SOLAR

PANEL WIRES

The wire size for the circuit between the solar panels

and power station was oversized to #2 which it just so happened that I

had a good bit of #2 left over from the feeds between my house and

power station. I can easily add more panels later (up to 12 more

ES-190-RL's) and not overload the conductor capacity. Each panel

puts out about 30.5 (Voc) volts so I wired two panels in series to get

61 Voc

(for 48 volt system) and each set of two panel wired in parrallel which

then connect to a 15 amp breaker (used "midnight solar" brand PV

disconnect and breaker). The reason for the 15 amp breaker is this:

each evergreen solar panel is 190 watts. I have 4 total. 4 x 190w =

760w , 760w / 48v = 15.83333 so a 15 amp breaker is needed. I can

have up to 3 more sets of 4 evergreen panels which requires (3) more 15

amp breakers which gives a total amperage for the circuit (circuit

meaning the feed of (2) #2 wires from the shack to the Midnight

solar PV disconnect) of 60 amps.

All this DC amperage will connect into my Outback Solar MX-60 mppt

charge controller. The mx-60 has a maximum continuous amp capacity of

60 amps so this works out well. ONe thing about the outback MX60 is

that you can have PV voltage up to 135vdc (max) but on the output side

to the batteries, it can be configured for 24v,48v,or even 60v systems

. I have my MX60 output configure for 48vdc because I have my (8)

trojan 6volt batteries wired in series to get 48volts. Outback

Power provides a nice wire distance

chart in their MX-60 manual on page 10.

Here is an excerpt from that chart that applies to my scenario (48 volt

PV array):

| Amps |

#8

|

#6

|

#4

|

#2

|

#1/0

|

#2/0

|

#4/0

|

50

|

14 feet

|

22 feet

|

36 feet

|

58 feet

|

92 feet

|

116 feet

|

172 feet

|

60

|

12 feet

|

19 feet

|

30 feet

|

48 feet

|

77 feet

|

97 feet

|

154 feet

|

The distance between my panels and the MX-60 is about 50

feet so #2 works out fine as I work my way up to 60 amps in the future.

The wire size for the ARE turbine was arrived

at by following

the wire size recommendations in the A.R.E 110 (low voltage) wind

turbine manual. They have a nice chart with wire sizes for certain

distances.

Batteries

I ended up purchasing Trojan brand

L16H batteries. They have a 20 hour rated Amp hour capacity of 420 amp

hours and weigh about 125lbs each. I heard great things about their

quality and I was able to get them at a decent price of $230 each from Brads Golf Carts out

of Belows Creek N.C (5515 Reidsville rd.). Brads was cheaper that

Batteries Plus so I went with Brads. Batteries Plus was the next

cheapest I could find for Trojans. Many

places that sell batteries

actually charge an extra "core" charge of up to 25 bucks a battery. You

can avoid this fee by giving them your old dead car/ lawn mower/ telco

batteries. Always

ask if there is a core charge and if they accept core exchange. And

remember to save your old batteries, they are actually worth

something.

**battery UPDATE** On September 19, 2008 I bought (8) more

batteries. Trojans were too expensive (around $300 each for L16H's) so

I bought (8) DEKA-L16 (320AH) batteries for $187 each from

www.batteriesplus.com. They did not require any core charge and they

threw in (for free) , the 18 connectors I needed to string the 8

in series and then in parallel with my current Trojans.

Note* -- I

just got word that Trojan L16H

batteries are now (Aug 2007) around $330 each!!!! Wow. I spoke with

Batteriesplus.com and they have an equivilent battery made by East Penn

for about $230 each but the 20 hour amp rating is about 370 compared to

the Trojan 20hr rating of 420 amps. I would get East Penn batteries now

if I had to until lead prices come back down. Batteries plus has free

delivery and have no core charge.

Note*

-- when pulling wire with your fish tape remember to

use plenty of lubricant - ie dishwashing detergent (cheap and

effective) or wire pulling soap (more expensive)

Note* -- I purchased

a copy of the NEC

2005 from the department of Insurance. If you are a do-it-yourselfer

like me you will be referring

back to this book frequently so you can pass State

inspection. The code book was about $80

including shipping. For a Electrical code book go to one of the

following links:

http://www.iccsafe.org/e/prodshow.html?prodid=5000L05&stateInfo=ppajZbnThlninRan8626|6

or

http://www.iccsafe.org/e/prodcat.html?catid=C-A&pcats=ICCSafe,C

or

http://www.iccsafe.org

then

click on iccstore drop down link at top of page, then click code

books

link.

NEXT PAGE >>

Rockriver.us

Rockriver.us Rockriver.us

Rockriver.us